Using a family font as a custom cabinet pull.

We are often asked to make custom door handles and custom cabinet pulls but not all requests can be met so I wanted to share with you a recent project we have just completed.

The home owner was remodeling his kitchen and wanted to use his simple but specific family business brand to create cabinet pulls. The client had 2 good digital files showing the front and side of his JJ font and as I shared in an earlier post we were able to use this to create a 3D model. Once the model was complete a mold for the single and double JJ 2 was created, wax replicas were made and shelled and finally steel castings were poured.

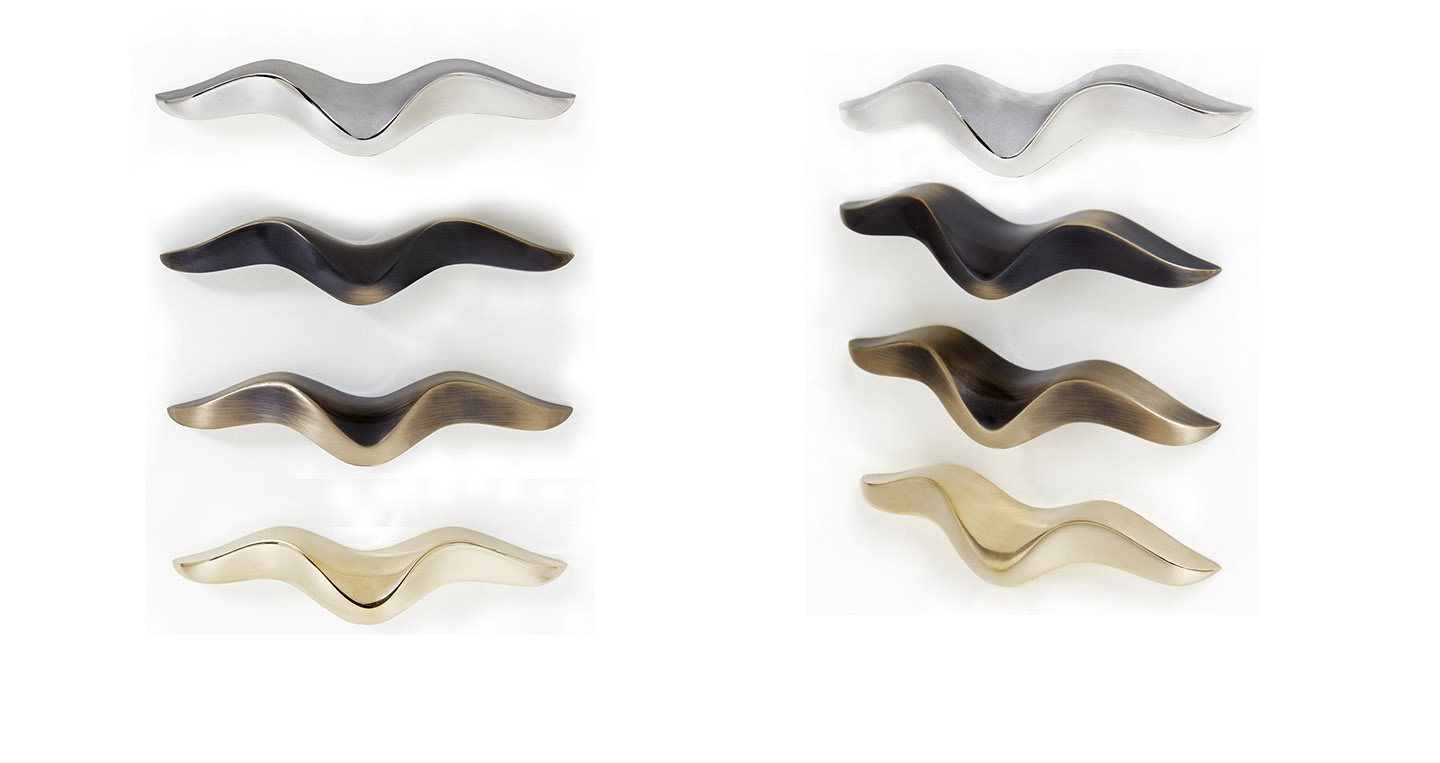

Brand Name Custom Cabinet Pull

The project was one we were happy to make for following reasons.

While the clients budget was fairly modest the design was not overly complicated and the 3D modeling could be done easily as there were excellent pdf files that showed the front and profiles of the J font and they were scaled to size. The quality of the files helped keep the modelling costs down and helped speed the production process.

The client had planned for the fact that cabinet doors are directional and can be either left or right handed and he creatively chose a design that could be inverted to make either a left or right pull. As the budget was limited this was a relief as we had only one tool for the larger J’s and the smaller double JJ’s.

The cabinet pulls were cast in stainless steel and were brushed by hand for a simple but chic look.

We made a total of 80 pulls from start to finish in 12 weeks.