Creating wax replicas of an original pattern is central to the lost wax casting process, a method often used in handcrafted stainless-steel hardware, artistic cabinet hardware, and custom hardware designs. In this post, I am showcasing the 12-inch Ergo stainless-steel cabinet pull, a sculptural piece from our Ergo Collection, to illustrate the steps from wax to finished product.

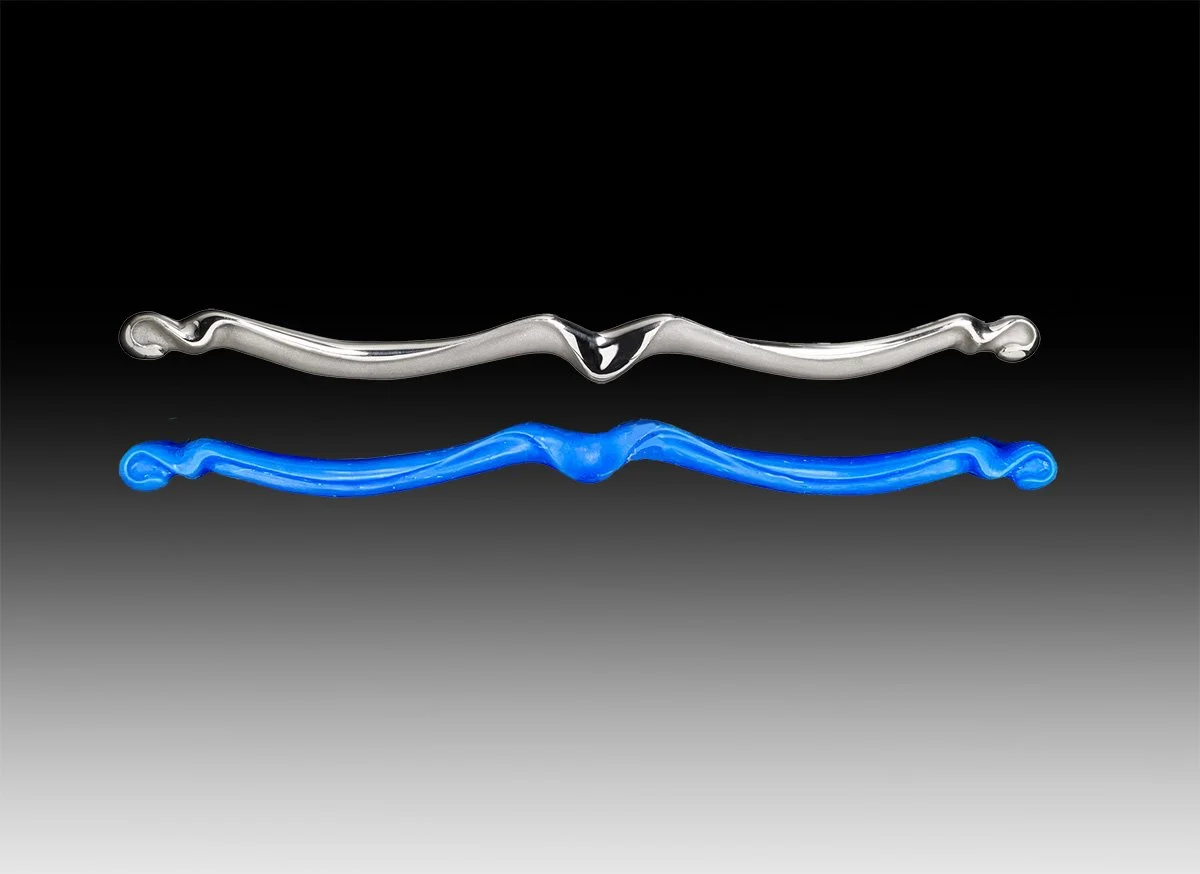

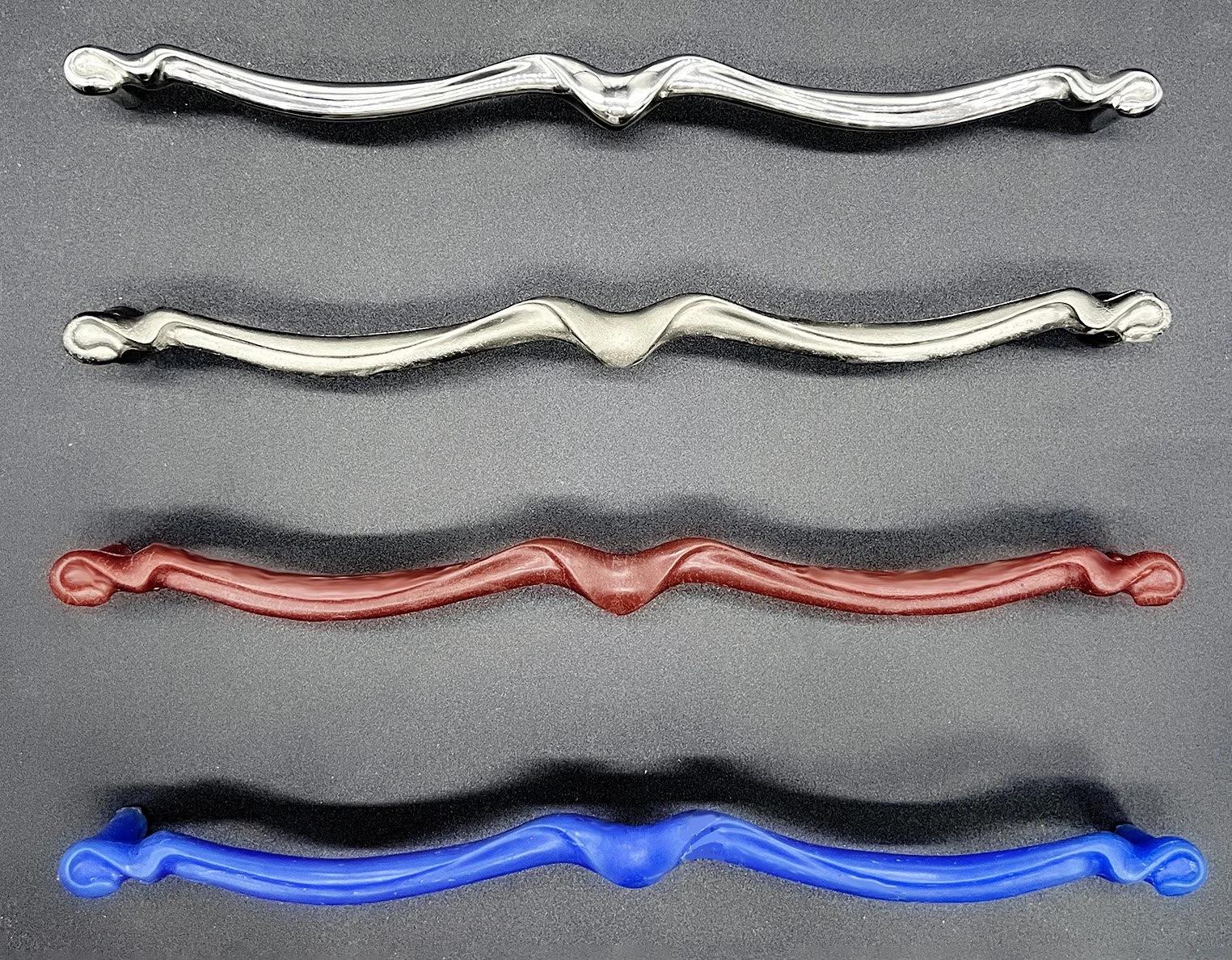

- The process begins with the original pattern, carved in hard, dense blue jeweler’s wax. This step requires precision, as it sets the standard for the final piece. The handcrafted, modern sculptural cabinet pulls in both our Ergo and Morphic collections begin here.

- Next, we create a wax replica by using a silicone mold taken from the original wax pattern. This allows us to produce multiple replicas while preserving the fine details.

- The initial casting in stainless steel reveals the form but not the finish as surface imperfections in the hardware need to be corrected.

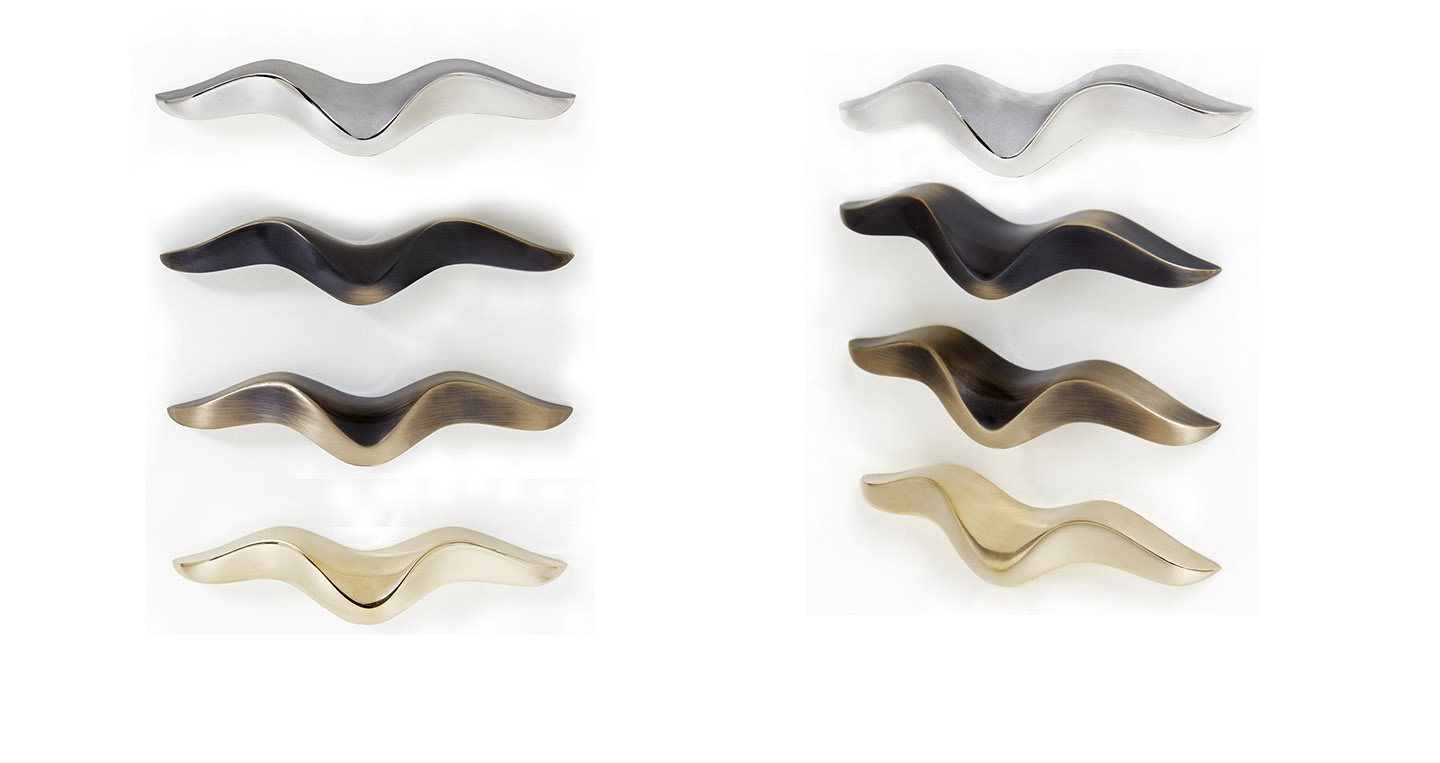

- Final piece finely sanded, spot welded if needed, sandblasted, sanded again, masked, and finished to two lusters—one satin, one highly polished.

Many hands-on artists like us use a two-part silicone rubber to create the mold. A rigid box holds the pattern in place, and then the pattern is covered in liquid silicone and left to cure. To prevent air voids that can occur inside the silicone when it is being poured, we place the mold inside a vacuum pot. The vacuum then pulls air out and draws any pockets of air caught in the rubber to the surface, thereby eliminating voids.

Silicone molds made from superior rubber, when stored properly at moderate temperatures with no ultraviolet exposure, can last decades. So, why make another mold?

- Scale of order. We are a small, limited-production company with a wide array of custom door handles and sculptural cabinet pulls and with over 300 molds ranging in size from 2” to 35”. Each mold typically yields one wax, and given the constraints of space, we only make a second mold when the size of the order or the popularity of the piece makes it worthwhile. Depending on the size of the piece, the wax can take from 45 minutes to two hours to become firm enough to be carefully removed from the mold. If production warrants, we will make a second or even third mold of the pattern to increase the speed of production.

- Customization. As artisans, we are often able to accommodate requests to shorten and sometimes lengthen a piece, provided it works within the aesthetic of the design. If the order is for one or a few pieces, then we pour each wax and modify each one by hand. If the number of pieces is significant, it makes sense to produce a second mold so we can speed up production.

- High-value item or budget. If a client’s budget permits, then for large door handles we will make a new mold to create a customized piece. This is especially the case when the piece is being slimmed down where its depth projects too far. If this were for one unit, we could make the adjustment by hand to the wax, but if four or six pieces are needed—especially when some are used as back-to-back pairs—it is important that all the pieces are exactly the same. That goal is very difficult to attain if the pieces are modified individually in wax; hence, a new mold.

We will be documenting the latter two cases in the weeks to come as we start work on a large, very custom order.