The skill set developed in creating bronze and steel door handles has proven an invaluable foundation for Martin Pierce’s art work. However, until we recently met Maria Ramirez-Adams we were unable to document the welding and patina techniques used in both hardware and art. Maria’s skill in capturing these moments will be the focus of this and other posts.

For those unfamiliar with the different types of welding www.thecrucible.org provides some very accessible well written pieces as well as instructional courses.

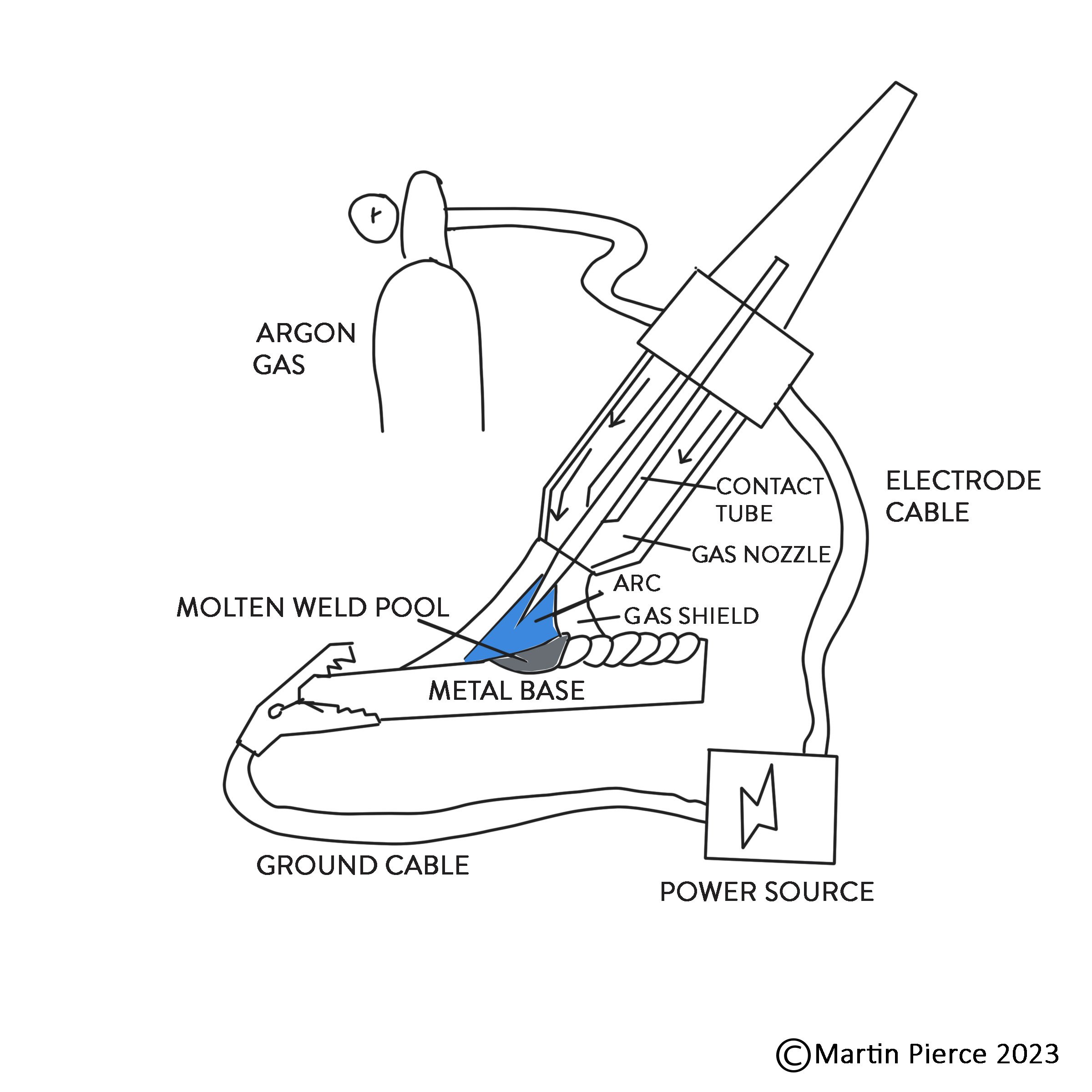

To assemble the components parts of a door handle we use the TIG welding method which does have a slow learning curve but is well suited to welding different thicknesses of metal and to welding very small pieces that need just enough weld to form a tight small bond. TIG welding can be used to weld either our 316 marine grade stainless steel or our silicon bronze castings. The abbreviation TIG stands for Tungsten inert gas also known as tungsten gas arc welding. TIG welding works by heating up the areas of metal to be connected and by inserting a welding rod of the same metal in this area to create a pool of melted metal that will form a connection or weld. The welding torch has a tungsten electrode that, on contact with metal, sparks to form an arc. While the electrode receives a constant current of power the voltage is controlled by a foot pedal which when depressed shortens and intensifies the heat of the electric arc.

Argon gas plays an interesting role, it’s purpose being to protect the welding process from contamination. The gas passes through the welding torch and shrouds the arc of the torch thereby preventing the weld area from being degraded by oxygen and other elements that could impact the integrity and strength of the weld. Argon gas is inert or inactive so it does not combine with elements in the air or work area so works perfectly as a shield.

To see Martin in action welding visit this informative video by Maria Ramirez-Adams.

The Hornet on Apple is a limited edition of 30 and is part of a collection of larger-than-life insects and diminished scale humans. The piece weighs 32lbs, measures 13"W x 10"D x 13"H and is a welding challenge. To attach the human to the apple the surface of the apple is heated first and then the welding torch is brought closer and closer to the human and apple and a small area of the foot and apple are melded or tacked together to form a temporary connection. The welding rod is then melted to fill in the remaining gap between the foot and apple.

In door hardware the non-operative door trim typically the requires fine TIG welding. For example, the operative Hedgerow passageway set has moving non-fixed parts and is assembled with through bolts and a spindle that activates the door latch. By comparison, non-operative version is fixed in place and the lever is welded to the backplate using the fine TIG technique.

Left: Showing weld before clean-up Center: Buffed Right: Operative Form