The final quarter of 2024 was action packed with fresh patinas for candleholders; Katydom making the cut for the Culver City Film Festival and the decision to make specific art pieces available for sale from our website.

So, continuing with this artistic vein, Martin Pierce we will be adding more art works to the Katydom Kingdom and Anne Pierce will be adding content to the story line that some may have previewed at the Regal Live L.A. when Maria Ramirez-Adams short was screened.

Candle Holders

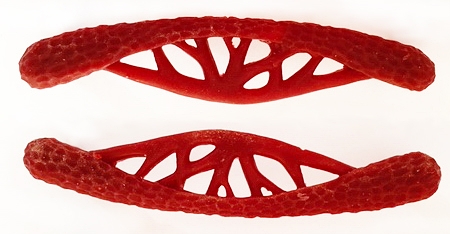

Hot red and green patinas are applied to heated bronze frogs to create a mottled finish similar to the coloring used by poisonous South American dart frogs to ward off predators. A more muted oil rubbed patina is available for those looking for less drama on the dining room table.

Katydom Characters

Seeing Martin’s sculptures come to life on a big screen and writing the narrative for Katydom has helped me focus on the roles and talents of the characters in this fictional kingdom. Specifically, I will be focusing on Katydids and the history and lore they inscribe as symbols on the fossilized wings shed by Katydid elders. Wasps, with their mud dauber masons will be added to the content and the structures they build will be captured in bronze.

Wasps in 2025 will be explored with emphasis on their craftsman skills, a departure from the current emphasis on athleticism.

Our mainstream occupation continues to be in creating unusual and beautiful door and cabinet hardware. We work with many designers helping to realize their design concepts with our designs and with custom designs fabricated for their projects. This will always be our creative core.