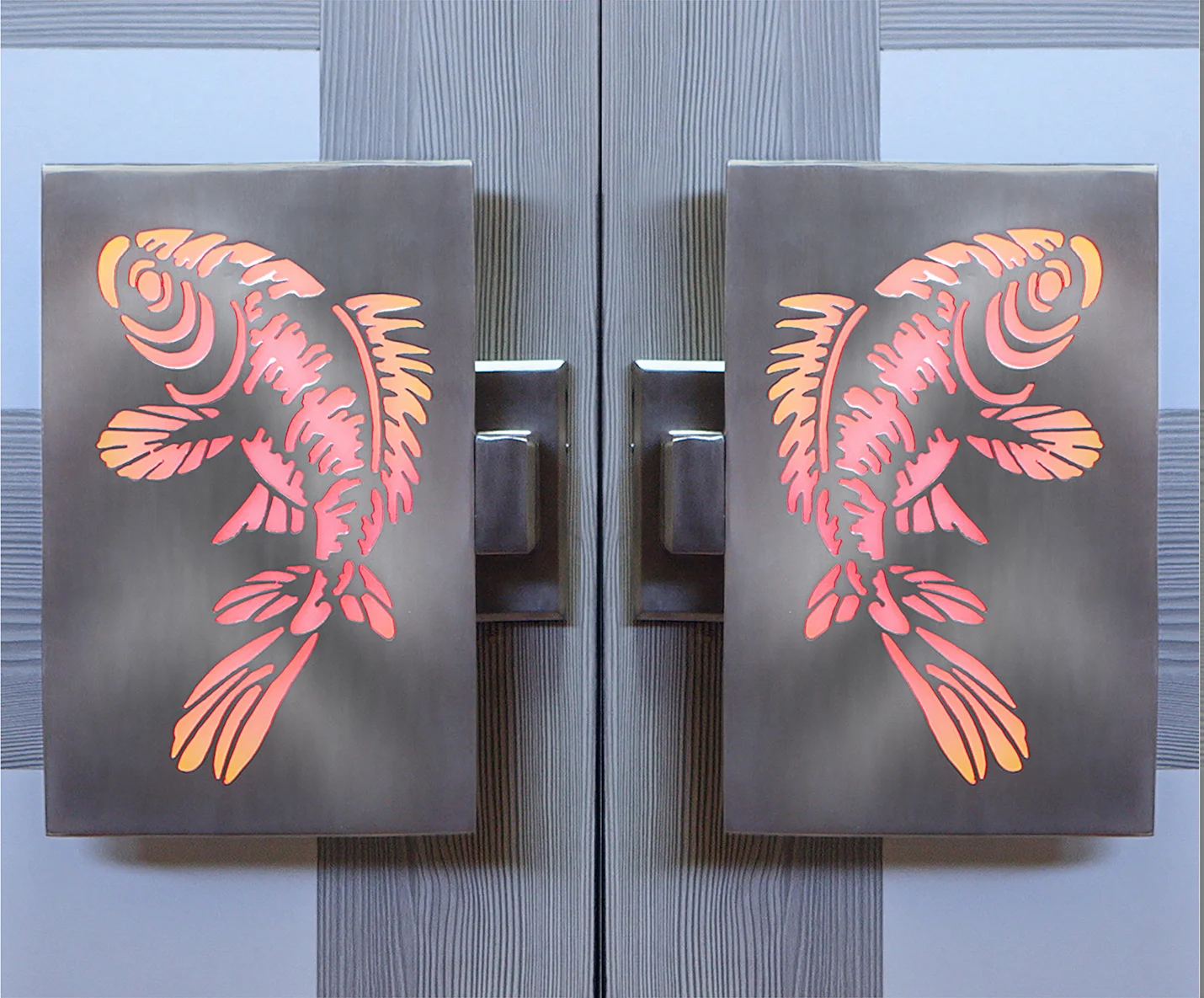

High end refrigerator manufactures like Sub-zero allow consumers to customize the look of their refrigerator by selecting handles that will complement the style of their cabinet handles but deciding what handles will work both aesthetically and practically can be a challenge.

As a door hardware designer and manufacturer we thought we should review some of our handles to see which do and don’t work well for this use.

Before reviewing the styles there are some practical points to consider;

1. You will need to order your refrigerator without the manufacturer’s standard issue handles and without the door being pre-drilled for the standard handle and also without the standard mounting brackets. The manufacturer will have their own door handle size and this is unlikely to be the same as the custom alternative.

2. The alternative custom handle can then be installed either directly onto the refrigerator door or on to a custom panel that is being fabricated by your kitchen cabinet maker.

3. Door pulls or grips rather than knobs work best as they allow you to more easily open the refrigerator if your hands are wet or full. A round or flat 90 degree angle is sadly the typical style for most refrigerator pulls and while these are easy to grip they are typically non-descript so use this as your practical starting point.

4. While there is no standard length that is recommended for a refrigerator the grip will need to be attached at 2 points to the door panel and will need to be sturdy enough in size and width to easily open the door without difficulty and without coming lose after repeated use.

5. You will need a professional cabinet maker or contractor to install the alternative handle in accordance with any manufacturer warranty guidelines.

Styles that work:

We see the kitchen area as a work space with surfaces that will need to be easily cleaned. My preference is to use more fluid slick styles without a lot of undercuts or filigree that will be difficult to clean. The Ergo and Morphic styles with the exception of the Morphic cylinder are good choices and look wonderful in stainless steel which will complement most refrigerator doors.

If you are using a wooden custom door then consider the Morphic and Ergo styles in bronze but with a baked enamel clear protective coating to help.